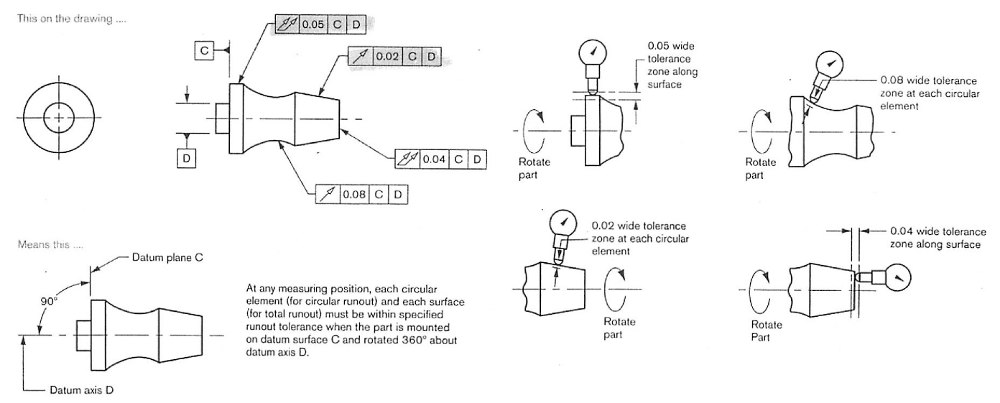

Think of a solid cylindrical part with flat faces at each end. This kind of tight control isn’t needed in all applications, but many parts could not function satisfactorily without such accuracy, especially in high-speed applications.Ī second way to apply total runout is to measure the surface variations on a flat surface.

It also ensures that they are stacked perfectly straight and that none of them is jutting out along the length of the stack, and also that the stack is located at its defined position in the correct orientation. Total runout ensures that all the coins in the stack are perfectly round. Let us understand how total runout works with the example of a coin stack. Every coin must be round and aligned within the tolerance zone subject to each other and the datum. Bends, if any, along the part length should not cause the part to breach the runout tolerance zone. In the case of cylindrical parts, besides controlling surface irregularities, total runout controls any axial variations in a part. All points on the surface must lie within the tolerance zone, and the difference between the highest and the lowest point on the entire surface must be less than the applied tolerance limit. It does so by specifying a datum axis and rotating the part by 360 degrees.Īny peaks and valleys on the surface are observed with respect to the applied total runout tolerance zone.

Total runout is a composite tolerance that controls the location, orientation and cylindricity of the entire surface simultaneously. VII Important points to remember What is Total Runout?

0 kommentar(er)

0 kommentar(er)